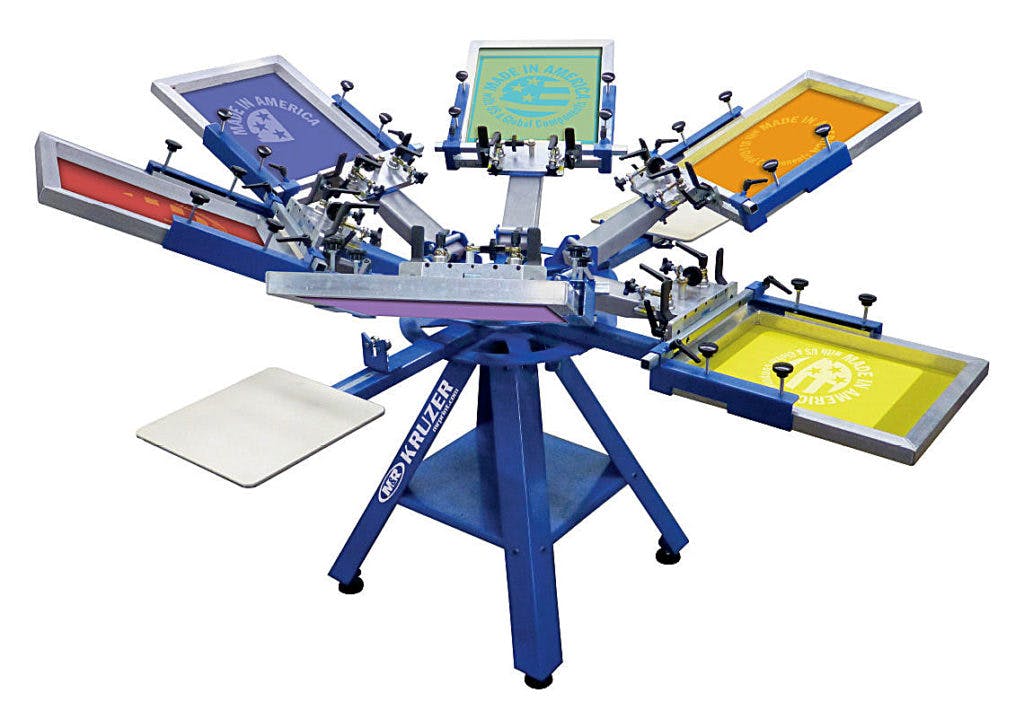

Screen printing machines for the decorated apparel market mostly fit into two categories: manual presses and automatic presses. Yes, there are belt printers that do the all-over prints, but they’re pretty rare. For the purpose of this post, we’re comparing the two main types.

As you would expect, automatic presses print much faster than manual presses. But there’s a lot more to it than that.

So I’m going to talk to our resident expert, Tom Ingling.

With a history in industrial supplies, micro-publishing, and aerospace manufacturing, Tom came to the decorated apparel industry in 2010 managing ClearSky24, a major printing company in Texas. He moved on to be the assistant manager at Shadowfax Graphics in 2012, and finally arrived at RushOrderTees in April 2013.

Within these decorated apparel companies, Tom served roles in finance, marketing, sales, procurement, art, prepress, new equipment investments, multiple production processes, process optimization, shipping, software development, automation, IT, management, human resources, facilities, maintenance, and quality control. Holy moly, Tom.

For any “thing” involved in custom apparel, Tom’s been involved with it in some way. And he’s happy to tell us all about it.

In this conversation, we’re going to go over costs, production speed, efficiency, and more. If you’re a new screen printer, thinking of buying an automatic machine, or just curious about the process, this post is for you.

Let’s dive in.

M: Hi Tom. So what makes an automatic press different from a manual?

Tom: Hi M. The automated functions that make a press considered automatic are, one– that platens (that hold the shirts) automatically advance from one station to the next, and two–the flood bar and squeegee raise, lower, and move automatically.

M: How fast is manual screen printing?

Tom: A manual press operator can print anywhere from 40 to 100 prints an hour, depending on the operator’s speed as well as how many colors are in the design, and whether or not the print requires a flash cure during printing.

M: How fast is an automatic press?

Tom: The current world record for t-shirt printing was set by Luis Omar Viera in 2013 at 2,139 prints per hour. But a previous world record was set by Rush Order Tees. In 2010, our founder and CEO, Mike Nemeroff, competed and personally set the record at 1,264 prints per hour.

M: That’s wild. Mike in the history books. Let’s get realistic though. What’s a more typical pace for an average screen printer?

Tom: Yeah, we can’t keep our printers pulling the equivalent of running 4-minute miles all day. A reasonable pace to maintain on an auto is 500-800 prints per hour.

It’s not all about the speed of the operator – the faster the machine can advance and stop, the faster it can print for any given speed the operator can load shirts.

Printing at these speeds requires two press operators – one to load shirts and one to unload.

M: How much faster is that than, let’s say, a DTG machine?

Tom: An automatic screen printing press is much faster. The fastest Direct To Garment Printer on the market as of 2018 is the Kornit Vulcan, which does 250 prints per hour – with a machine that costs around $800,000. A $34,000 automatic screen printing press can print 500 prints per hour.

M: How does that compare to other customization methods?

Tom: Other processes, print and cut vinyl, dye sublimation, embroidery, laser transfers, and others are at least an order of magnitude slower than automatic screen printing.

M: How does it compare to other types of printing?

Tom: While 500-800 prints per hour may sound fast and it is the fastest process for decorating apparel, compared to a lot of the commercial printing industry, it is incredibly slow. An offset press can run as fast as 100,000 prints per hour.

M: How much is a manual vs automatic screen printing press?

Tom: Typical cost for an entry-level manual screen printing press is about $5,000 and might produce around 60 prints/hour with one employee.

Typical cost for an entry-level auto screen printing press is $34,000 and might produce 500 prints/hour with two employees.

M: What do those prices mean for the overall value of the machines?

Tom: One way to compare is to ask: how many prints per hour do you get per dollar of machine cost? The manual press costs $83 per print per hour, and the auto costs $68 per print per hour.

M: Are there other costs to factor in?

Tom: Yes, there’s more to total cost then press cost. Two employees in an hour on an auto can produce 500 prints, while two employees on two manuals for an hour produce only 120 prints. So the labor costs per-print of the auto are only 24% the labor cost on the manuals.

Over time, labor will be a much larger factor in total cost than the upfront machine cost. Over 5 years of production, your labor costs for two manuals or one auto could easily exceed $300,000. That dwarfs the original $10,000 for two manuals or $34,000 for an auto.

M: Wow, I didn’t realize labor is such a huge factor.

Tom: Looked at another way, assume a shop has enough work to keep one auto busy. They can buy the auto and print 500 shirts per hour, or buy 8 manuals to achieve about the same output.

But the labor costs of the manuals will be four times higher – it takes 8 employees to print on eight manuals, but only two employees to print on one auto.

The auto costs $6,000 less than the eight manuals right off the bat ($34,000 auto vs 8 x $5,000 = $40,000 for manuals). Over five years, the labor savings of the auto might be around $900,000!

M: So if the auto costs less per-print to purchase, and then much less per-print in labor to run, why would any shop that can afford an automatic press and keep it busy still use manual presses?

Tom: For small orders, the time to set up, get an approved print, and tear the job back down takes a lot of time compared to the actual printing. You don’t want an expensive press to spend most of its time sitting around during setup and teardown of jobs.

To actually come out cheaper, that automatic press has to print. It doesn’t matter much that the press can print very fast if printing isn’t what the press spends most of its time doing.

So the larger the job, the bigger the advantage of the automatic press, and the smaller the job, the bigger the advantage of the manual press.

M: That sounds like a lot for the average print shop take into account.

Tom: To make press choice extra confusing, printing on a manual press takes longer the more colors there are in a design. But printing on an automatic press takes the same amount of time per shirt regardless of how many colors are used.

So the more colors in a design and the higher the quantity, the more likely it is to print on an auto. The fewer colors and fewer shirts, the more likely it is to print on a manual.

Also, dark shirts, which require an underbase and a flash cure while printing, are more likely to head to autos, while light shirts are more likely to head to manuals.

M: [laughs] Example of why the answer to most questions in the T-shirt business is “it depends”. Are there any more factors we need to account for?

Tom: Absolutely. Some items also require extra loading time. For example, printing on jackets or other multi-layer material requires using a hold-down frame to clamp each item once loaded and removing the clamp to unload.

Anything that slows down the process like that favors manual presses – if you cannot load and unload the items quickly, the advantage of being able to print quickly is lost.

So, other things being equal, sleeve prints on long-sleeve shirts are more likely to go to a manual due to the relatively long load time.

M: What is the difference in print quality between automatic and manual screen printing?

Tom: Automatic presses achieve more consistent prints than all but the very best of manual printers. For printing line-art, either kind of press can achieve high consistency.

But for printing gradients, automatic presses generally have an edge. Gradient jobs usually go to auto presses, unless they have very few shirts or low colors, in which case they go to an expert manual printer.

M: So is manual printing going away anytime soon?

Tom: RushOrderTees has twelve manual presses and continues to do a lot of printing on them, but manual press use will decrease as Direct-To-Garment printing improves.

Manual screen printing has been around as a process for around a thousand years, beginning in China during the Song Dynasty. While it will continue to be around for niche applications or hobbyists for a long time, manual screen printing is beginning to be replaced by Direct-to-Garment printing.

M: Have there been advances in screen printing to keep up with DTG (Direct-to-Garment)?

Tom: Screen printing is a mature technology that achieves few efficiency gains from year to year. Direct-To-Garment printing, like other high-tech devices, is improving rapidly.

Given the current disparity in cost per print speed, it may be a long time until Direct-To-Garment printers replace automatic screen printing presses.

But they are already starting to replace manual presses, a trend which will surely accelerate.

M: Thanks Tom, talk to you again soon.

* * *

For more information about screen printing vs DTG printing, check out my post featuring a 10-round battle between the two print methods.

Happy designing,

-M

Imri Merritt

About the Author

A graduate of the Multimedia program at the University of the Arts in Philadelphia, Imri Merritt is an industry veteran with over 20 years of graphic design and color separations experience in the screen printing industry.